Peanut Processing Machines and Equipment

Peanut butter processing machines and equipment

Probst & Class develops and manufactures machinery and equipment for the processing of peanuts for the production of peanut butter. The most typical end products are peanut butter and peanut sauce.

Every end product needs its own bespoke machine configuration.

Our strategy for perfect customisation: puclab.

Peanut processing with PUC colloid mills

Probst & Class colloid mills are predestined for grinding a wide variety of nuts and nut-like fruits. Successful applications include Almonds, cashews, hazelnuts, pistachios, macadamias, pecans, Brazil nuts and peanuts.

Based on the experience of the last decades, we present here the proven application possibilities of Probst & Class colloid mills in combination with the natural product PEANUTS. Almost all requirements can already be met from the standard product range, more specific solutions are available for special requirements, or can be adapted and developed together.

The most classic application is the grinding of roasted peanuts into very fine peanut paste or peanut butter. This is done in a single grinding pass, free from the addition of any fluids or additives. The peanut can be ground with or without the skin. The skin contains numerous substances with positive health effects such as antioxidants, phenolic acids, flavonoids and resveratrol, in significantly higher concentrations than the peanut itself, making it increasingly interesting for many customers.

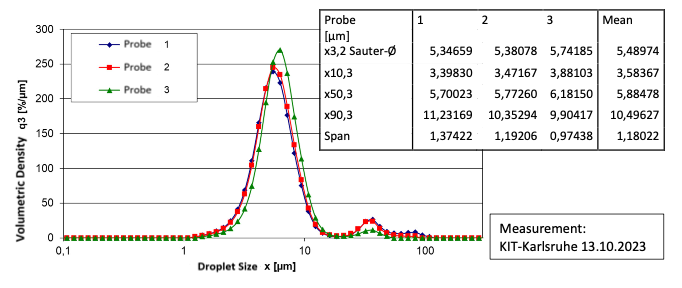

The achievable fineness or particle size distribution after one pass through the mill with a grinding gap setting of 50 μm is outlined in the following graphic:

The grinding gap width of 50 μm is clearly visible here, as is the almost 10 times smaller mean value of the distribution resulting from the particle interaction during the grinding process.

As with all natural products, tracing back to the most uniform initial conditions possible is a decisive factor for a stable process and repeatable results.

Best practice procedure

In general, using the smallest milling gap of 50 μm will achieve the finest result. A wider gap will shift the particle distribution towards a bigger mean but will not produce anything near “crunchy” Peanut-Butter! The maximum gap setting will produce a nut paste of peanuts where particles are still tangible but because of the particle interaction in the milling gap this is not a linear correlation. There is the possibility to feed the butter from the first pass to the mill for a second pass, with results in an even finer paste, if necessary. Optimally this could be done with in a dual serial mill configuration, starting with straight cut milling gears, followed by finer, cross-cut milling gears. This also allows for intermediate cooling of the paste to limit influence of over temperature. In our experience, high-quality roasted peanuts with consistent process parameters, milled once with a small milling gap, result in a peanut paste with a fineness that is sufficient for nearly all applications.

One essential key element for a good result is the preparation of the nuts ahead of milling.

First Step: Roasting.

We learned that the humidity content must be below 2% and is perfect between 1-1,5 %.

Second Step: Cooling

The nuts should cool down to ambient temperature after roasting in open atmosphere. Forced cooling noticeably impacts the milling results and is not recommended without prior testing. After reaching ambient temperature the peanuts should be stored in closed / airtight containers (no vacuum needed for short term storage) to prevent them from absorbing moisture again.

The lower the moisture the more liquid the butter because the more oil is released during the grinding process. This makes the butter more flowable and it also feels smoother. Any humidity present in the nuts binds the nut oil into an emulsion, which is undesirable.

The nuts should be around low ambient temperature when they are milled. A temperature a few degrees higher may result in a higher viscosity, higher generated temperature during milling and a lower flowrate, if very fine results are required.

Specialized Applications

We have successfully adapted our mill to accommodate very specific customer requirements. Some Examples are:

Milling gear with wider gap then standard and reduced cutting teeth depth to produce a coarser peanut paste, (but still finer than “crunchy” Peanut butter) for use in chocolate & peanut butter pralines.Milling gear that accepts peanuts with higher water contents and advanced oxidation of oils, after a longer and unsealed storage periods, for non-food applications.Serial Mill Setups that allow for the addition of peanut flour in higher quantities after than normal the first milling step.

As orientation for productivity these values can be used.

Measurements were taken with smallest milling gap, and can nearly double for the widest setting. N120 11,0 kW 400... 500 kg/h

N160 18,5 kW 1000...1400 kg/h

N180 37,0 kW 1200...1800 kg/h

Our international sales team will assist you with all questions regarding your product requirements and will be glad to refer you to a contact person in our R&D department or other departments if required.

Probst & Class as a supplier to the food industry

Probst & Class mills have been used in state-of-the-art food processing for 80 years. Using a PUC, both small producers and large industrial groups manufacture high quality products from nuts. The high manufacturing quality of PUC machines usually guarantees a service life of several decades. The supply of spare and wear parts, even for very early models, guarantees a secure investment and low total cost of ownership.

Find your ideal machine, reliably and quickly

In the almost 100-year history of Probst & Class, there is one constant: Practically every end product needs its own individual machine configuration!

Two special features of Probst & Class guarantee the highest satisfaction and loyalty of our customers: The simple convertibility of our machines and our approach to customisation.

What has been part of our success for decades is now a strategy. We call this strategy puclab.

puclab is more than a development lab

- System consulting: Holistic concepts for the construction of new systems and the conversion of systems to other products

- Outsourced R&D for our customers' wet grinding, mixing and degassing processes

- Preliminary trials to help decide on the optimal process

- Further development of processes in case of changed specifications

- Application database with test set-ups, test results and videos

puclab – Pilot

Make an appointment for preliminary tests in our pilot plant.

We give you and your product as much time as needed. Together with your technicians/engineers, we determine the best possible configuration for your new PUC machine in our test lab and plan its integration into your process.

puclab – On-Site

Test a PUC mill in your plant or laboratory.

Talk to our technical support to define the requirements for your process and product. We then provide you with a suitable machine, free of charge, and offer support for your in-house trials.

puclab – Remote

Send us your raw materials for testing.

Based on your specifications and materials, we determine the best machine configuration for your end product in our technical centre. Using different grinder sets and settings, we can calculate within a few hours how your new PUC mill needs to be configured, without charge.

Contact our sales department

Still unsure about the best way to proceed?

Simply contact the sales team. We are happy to help you.

- Bitumen Emulsifier: Machines for the Production of Bitumen Emulsion

- Colloid Mills - Try before you buy

- Machines and Colloid Mills for Fungicide Production

- Machines and Colloid Mills for Herbicide Production

- Machines and Colloid Mills for Insecticide Production

- Production of Emulsion Paints with Colloid Mills

- Industrial peanut butter making machine and equipment

- Machines and Colloid Mills for Fertiliser Processing

- Machines and Colloid Mills for Processing Plant Protection Products

- Machines and components for the production of animal feed

- Machines and industrial equipment for the production of vegan cream

- Machines for grease processing and grease post-treatment

- Machines for processing and post-treatment of industrial lubricating oils

- Machines for Processing Soybeans

- Machines for the commercial production of facial cream

- Machines for the Industrial Production of Mayonnaise

- Machines for the processing of collagen

- Machines for the production of baby food

- Machines for the production of hand cream

- Machines for the production of jam

- Machines for the production of meat substitutes

- Machines for the production of plant-based cream alternatives

- Machines for the production of plant-based milk alternatives

- Nut mills and machines for nut grinding

- Processing of Paints and Coatings with Colloid Mills

- Processing of Printing Inks with Colloid Mills

- Processing of Digital Printing Inks with Colloid Mills